Products

Machining Center

| Longmen processing center for aluminum profile extrusion die |

| Product Type: |

Brief Description: |

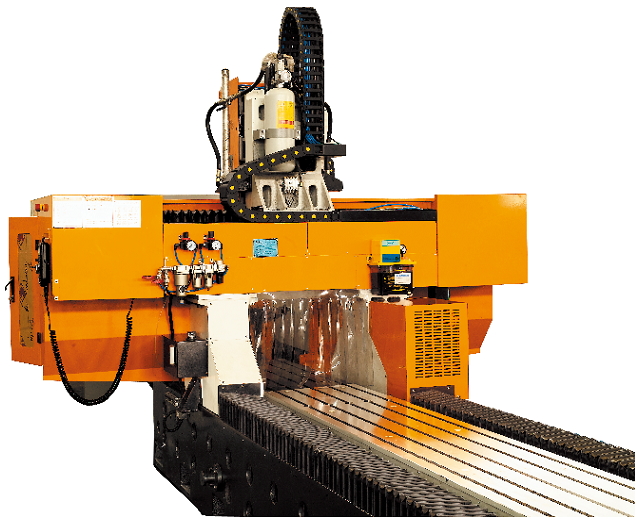

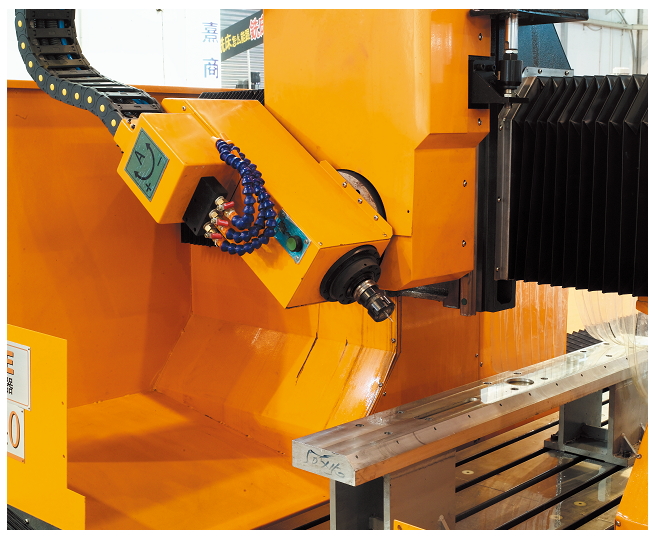

型材動柱式龍門加工中(zhong)心(xin)

Section Moving Column Machining Center In Longmen

FWG-L540 / L560 /L540A/L560A

|

項目 |

FWG-L540 |

FWG-L560 |

FWG-L540A |

FWG-L560A |

||

|

行 |

X軸行程mm |

4000 |

6000 |

4000 |

6000 |

|

|

Y軸(zhou)行程mm |

800 |

1070 |

||||

|

Z軸行程mm |

350 |

500 |

||||

|

旋(xuan)轉軸(A軸)擺動主(zhu)軸頭 |

|

旋轉角(jiao)度?90? |

||||

|

旋轉軸(A軸)工件旋轉軸 |

|

旋轉角(jiao)度?90? |

||||

|

龍門寬度mm |

650/400 |

650 |

||||

|

工作(zuo)臺面到橫梁(liang)底面距離(li)mm |

500 |

500 |

||||

|

龍門過(guo)工件高(gao)度立式/臥式 |

400/480 |

400/480 |

||||

|

主軸端面至工作臺面距離mm |

110~460 |

負41~459(立式時,有效(xiao)300) |

||||

|

主軸(zhou)中(zhong)心至工作臺面距離mm |

|

130~630(臥式(shi)時,有(you)效300) |

||||

|

主軸端面至(zhi)工作臺面側面最大距(ju)離mm |

|

負(fu)100 |

||||

|

主 |

主軸規(gui)格 |

BT-40 |

ISO-30主軸(意大(da)利) |

|||

|

主軸額定轉速rpm |

|

6000 |

||||

|

主軸最高轉(zhuan)速rpm |

12000 |

24000 |

||||

|

主軸額定扭矩Nm |

35 |

11.9 |

||||

|

刀 |

刀庫形式(shi) |

傘形刀庫 |

排(pai)式刀(dao)庫 |

|||

|

刀庫(ku)容(rong)量 |

8把/12把 |

8把(ba) |

||||

|

移動 |

X軸快速移(yi)動(dong)m/min |

40 |

30 |

|||

|

Y軸快速移動m/min |

30 |

24 |

||||

|

Z軸(zhou)快速移動m/min |

30 |

24 |

||||

|

工 |

工作臺尺寸(cun)mm |

4000X500 |

6000X500 |

4000X500 |

6000X500 |

|

|

工作(zuo)臺最大承重kg |

1500 |

2000 |

1500 |

2000 |

||

|

工件最(zui)大寬度 |

500 |

500 |

||||

|

龍門(men)過(guo)工件高度立式/臥式 |

400 |

400/480 |

||||

|

CNC第四軸 |

選配 |

選配 |

||||

|

動力 |

主軸電機功率(lv)kw |

5.5/7.5 |

7.5/8.6 |

|||

|

X、Y、Z、A軸電機功率(X軸配減(jian)速機) |

3.5/2.2/2.2 |

3.5/2.2/2.2/0.5 |

||||

|

精 |

X軸定位精度mm |

?0.02(全(quan)閉環,發格光柵尺) |

?0.02(全閉環,發格光(guang)柵尺) |

|||

|

X軸重復定位精度mm |

?0.01 |

?0.01 |

||||

|

Y、Z軸定位(wei)精(jing)度mm |

?0.015 |

?0.015 |

||||

|

Y、Z軸重(zhong)復定(ding)位精(jing)度mm |

?0.008 |

?0.008 |

||||

|

潤滑 |

潤滑系統 |

集中潤滑 |

||||

|

冷卻系(xi)統(tong) |

切削液(ye)冷卻 |

|||||

|

排屑 |

雙螺旋(xuan)+鏈板式排(pai)屑器 |

|||||

|

機床 |

機床外(wai)形尺寸(長X高X寬)mm |

7500X1800X2400 |

9000X1800X2400 |

7500X1800X2400 |

9000X1800X2400 |

|

|

機床(chuang)總重T |

7 |

9 |

9 |

9 |

||

|

機床輸入電壓功率 |

380V/25KVA |

|||||

|

數控系統 |

三菱/西門子/發(fa)那科 |

|||||

型材動(dong)柱式龍門(men)加工中心

Section Moving Column Machining Center In Longmen

FWG-L540 / L560 /L540A/L560A

產品特點

Product Features

|

|

|